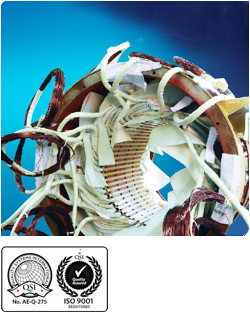

Rewinding

K&J has been providing complete rewinding solutions for Stator, Rotor & Excitor for all types of alternators and manufacturers for the past 10 years. Each work is quality assured by a well trained and experienced division head using the best testing facilities available in the industry.

DC Motors and HT

K&J electrical team specializes in high voltage repairs and provides all ancillary mechanical coil manufacturing. They are also capable of carrying out operations on site to minimize down time.

AMC

The division can also undertake AMC for the entire motor fleet available at a clients location. This ensures that the motors are always at their best possible as service and maintenance is carried out on a pro-active basis assuring maximum efficiency at all points of time through their operation.

Process Flow

Scope of work includes:

- Dismantling

- Trouble Shooting

- Service or Overhauling

- Varnishing & Baking

- Assembling

- Testing

Currently the facility has the ability to execute up to 2500 KW. All of the process other than onsite work is done in a closed, dust free and air conditioned environment by well experienced technicians thus adding to the life of the equipment.

Product support

At K&J, the belief is to be as close as possible to the customer so that any problems at any point of time can be properly addressed and resolved within the maximum possible time limit. To achieve this the company has invested heavily into ensuring that:

- 365 days 24/7 of service availability

- Specially equipped vehicles to attend and service in the shortest possible time

- Excellent response time for attending any kind of problems at sites